Epoxy for Automotive Applications

Use CPD Epoxy Systems to manufacture automotive components that are heat resistant, mechanically robust, with excellent adhesive properties.

In the automotive sector, CPD Epoxy Systems serve many purposes including enhancing mechanical strength of components, providing heat resistance, curbing rust and corrosion, reducing weight, mitigating vibration, and facilitating structural bonding. Specifically, our epoxies play a crucial role in the production of automotive composite parts such as suspension system components, drive shafts, and chassis—the primary load-bearing portion of the frame.

The implementation of CPD epoxies in vehicle manufacturing significantly trims down vehicle weight, leading to substantial fuel efficiency improvements. This, in turn, results in reduced emissions, offering benefits for both you and the environment.

Applications:

Adhesive Epoxies

CPD and Polytek Adhesive Epoxy Systems demonstrate a broad range of adherence to various materials, encompassing metals, composites, plastics, rubber, foams, ceramics, and wood. They possess substantial tensile strength, bond strength, high-temperature durability, and superior chemical resistance. Incorporating CPD or Polytek structural epoxy adhesives in your application can significantly enhance performance compared to conventional fastening methods.

Casting Epoxies

CPD Casting Epoxy Systems serve a multitude of purposes in various industries, primarily for creating robust, heat resistant tooling or fixtures. Offerings are designed to allow a range of casting thicknesses, allowing you to choose the product best suited to your application. To enhance durability and performance, many systems are filled to allow enhanced durability or temperature tolerance needed for parts in the automotive, aerospace, and sports industries.

Compression / Press Molding Epoxies

CPD Epoxy Resin Systems are widely recognized for their superior mechanical properties, impressive heat resistance, and remarkable dimensional stability, making them a preferred choice in compression molding. Upon curing, your epoxy parts display exceptional strength and robustness, establishing their suitability for applications demanding sturdy molded components including, but not limited to, aerospace components, sports equipment, electrical insulation, and structural composites.

Filament Winding Epoxies

CPD Epoxy Systems are extensively used in filament winding processes due to their beneficial properties and exceptional structural integrity. Filament winding is a manufacturing process utilized in the production of cylinders, pipes, tanks, pressure vessels, structural tubing, and bushings. CPD epoxies are frequently employed by manufacturers seeking to fabricate advanced composite materials to yield products that are lightweight and durable.

Infusion / Injection / Resin Transfer Molding Epoxies

CPD Infusion Epoxy Systems produce lightweight, high-strength composite parts with superior mechanical properties, resistance to corrosion, and dimensional stability. They have low viscosity and high reactivity and are ideal for impregnating reinforcing fibers such as carbon fiber or fiberglass when utilizing vacuum infusion processes. CPD epoxy infusion resins are employed in the aerospace, automotive, marine, wind energy, and sporting goods industries who rely heavily on lightweight, durable composite materials to meet their stringent requirements.

Laminating / Wet-Layup Epoxies

CPD and Polytek Laminating Epoxy Systems are engineered to accommodate many wet-layup applications. These epoxy systems are instrumental in crafting lightweight, robust composite structures capable of enduring sustained stress, even under the most severe conditions. Their bonding capacity extends to a diverse range of materials and reinforcing fabrics, demonstrating exceptional resistance to moisture, heat, and fatigue. CPD and Polytek Laminating epoxies exhibit superb physical properties at room temperature with the option to post-cure to increase performance.

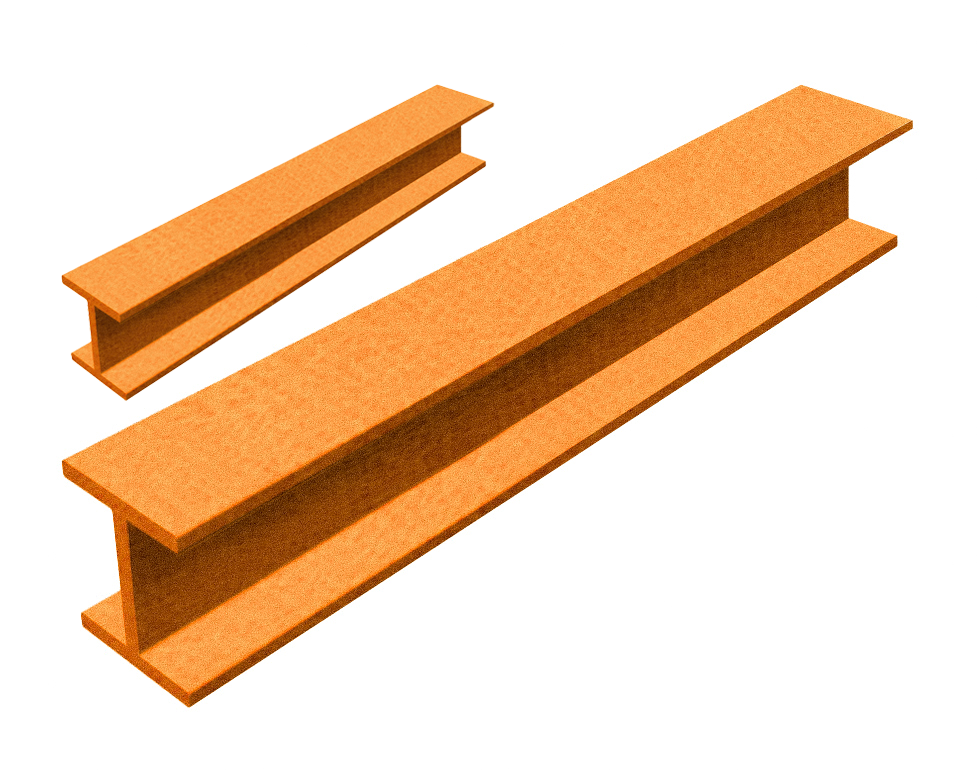

Pultrusion Epoxies

CPD Epoxy Systems for Pultrusion offer a cost-efficient method for producing highly rigid composites that are viable for alternatives to conventional construction materials. The CPD composite materials offer the flexibility of being engineered for varying degrees of flexural, impact, tensile, compressive strengths, and structural shape. The utility of pultruded composite profiles is underscored by their lightweight construction, superior strength, corrosion resistance, and ease of installation.

Surface Coat Epoxies

CPD Coating Epoxy Systems are widely recognized as the preferred solution in a multitude of industrial applications due to their superior protective characteristics. These properties, which include defense against abrasion, turbulence, oxidation, corrosion, temperature fluctuations, fire, moisture, impact, vibration, shock, and compression, make CPD epoxies an ideal choice. Industries such as aerospace, automotive, marine, and sporting equipment frequently experience such conditions, thereby favoring the usage of CPD epoxy systems for coating applications.

Bio-Based Epoxies

By using our bio-based resin, you can produce durable composite parts while also making a positive impact on the environment. Traditional epoxy products are derived from crude oil, while our bio based products are derived from agricultural by-products. Performance remains a paramount objective for any CPD product. Therefore, we've ensured that our formulations meet your high manufacturing standards.