Use Polytek® urethane rubbers to make high-performance molds and parts.

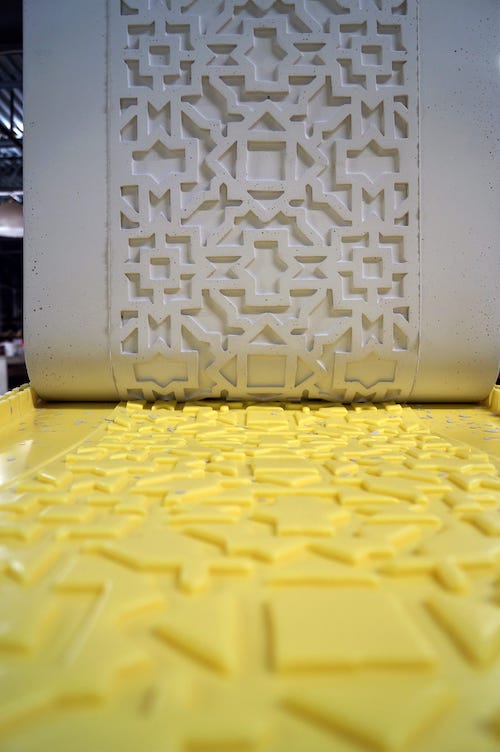

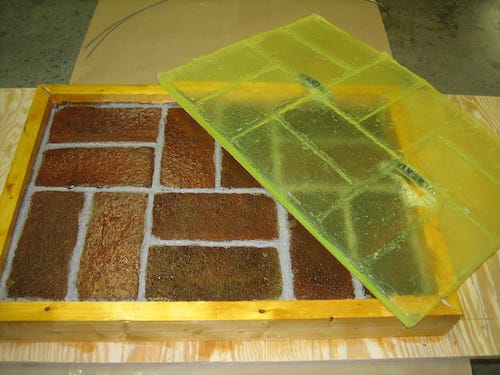

Polytek® manufactures a high-quality line of two-part, room-temperature curing (RTV) polyurethane rubbers that can be poured, brushed or sprayed to make molds or flexible parts. Polyurethane mold making and casting rubbers are economical, incredibly versatile, and capture excellent detail.

Select a product line below to learn more or continue to scroll to review product line features and common applications:

Product Line Features

- Type: Two-part polyurethane rubbers

- Room temperature curing (RTV)

- Shore A20 to D45 hardness options

- High-strength, abrasion-resistant, long lasting molds and parts

- Pourable, brushable and sprayable options

- Polyurethane molds are most often used to cast concrete, plaster, wax and polyurethane, polyester, and epoxy resin (release agent required in many cases)

Common Applications

Application Examples