Mold Making: Mold Rubber Hardness

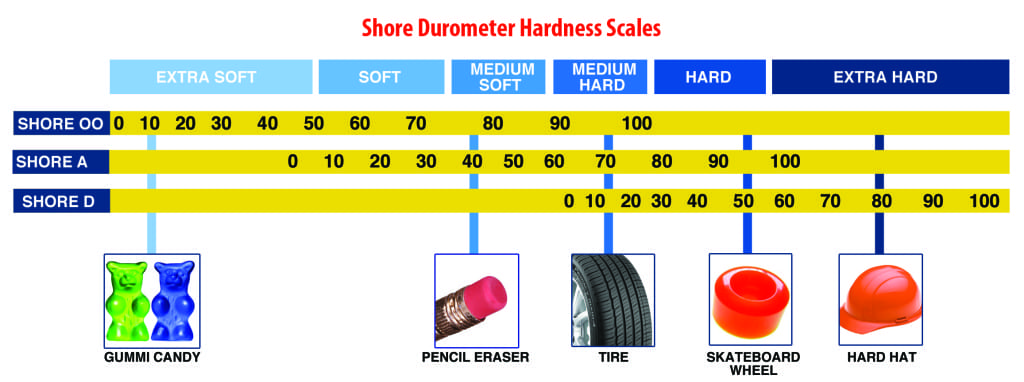

The hardness of rubber can be measured using Durometer Shore Hardness Scales [Figure 1].

Shore Hardness measures the resistance of a material to indentation.

We measure our rubbers using the Shore OO & Shore A Scales, and we measure our very hard rubbers and plastics with the Shore D scale.

The higher the number, the harder the rubber.

Figure 1: Durometer Shore Hardness Scale

How It Is Measured

Rubber hardness can be measured using a Durometer. Holding the rubber firmly and level, press the Durometer’s needle onto the rubber’s surface [Figure 2]. The Durometer in the photo below only measures Shore A hardness.

Figure 2: Durometer

Why Mold Rubber Hardness is Important

It is important to select a mold rubber that, once cured, can be removed from your model or casting easily and without causing damage.

Here is an example of a model that would require a softer rubber [Figure 3]. Models with undercuts and delicate protrusions (e.g., the individual fingers on an extended arm of a clay sculpture) will require a soft, flexible rubber.

Figure 3: PlatSil® 71-20 was used to create this mold. This rubber has a Shore Hardness of A20.

Harder rubbers should be used for flat, simple models or castings. An example would be a paver stone [Figure 4]:

Figure 4: Poly 75-70 Polyurethane Rubber was used to make a mold of a textured paver stone

Mold Thickness Matters

It is important to keep in mind that the thickness of mold will affect its flexibility. A thin mold (~0.5”) made of Poly 74-20 (Shore A20) is going to be much more flexible than a thick mold made from the same rubber (~3.0”).

Polytek Mold Rubbers: Hardness is in the Product Name

Polytek polyurethane and silicone rubbers range from Shore OO30 to D45. Looking through our product line, you will notice that we indicate Shore Hardness right in the product name (the last two digits):

Polyurethane Rubber Examples:

Poly 74-20 = Shore A20

Poly 74-45 = Shore A45

Poly 75-80 = Shore A80

Polygel® 35 = Shore A35

Silicone Rubber Examples:

TinSil® Gel-10 = Shore A10

TinSil® 70-25 = Shore A25

PlatSil® Gel-OO = Shore OO30

PlatSil® 71-20 = Shore A20

PlatSil® 73-40 = Shore A40

Video Demonstration

In the video below, the flexibility of various rubbers is demonstrated: