Tek-Tip: Repairing Torn Rubber Molds

If a tear develops in your polyurethane rubber or silicone rubber mold, one of the following options may help to repair it.

General Tips & Notes

- Before applying adhesive to torn molds, clean the affected area thoroughly. Denatured alcohol is a good option for this, but care must be taken with respect for health and flammability hazards.

- Generally, block molds are easier to repair than thin blanket molds because there is more surface area.

- When repairing thin blanket molds with adhesive, consider adding a layer of fabric (e.g., TieTex® Fabric) to better reinforce.

- If a tear occurs within 24 hours of creating the mold, you may be able to use the same mold material to repair it.

Repairing Polyurethane Rubber Molds

For polyurethane rubber molds, like 74-Series, 75-Series, and Polygel® rubbers, the ideal option for repairing tears is PolyBond. PolyBond is a two-part, flexible, polyurethane adhesive that has a 1A: 3B mix ratio (by weight), a 3-minute pour time, and a 15- minute cure time.

Epoxy adhesives, like PolyPoxy ® Quick Stick Adhesive, could also be used to repair a tear; however, they are non-flexible and will begin to crack if they are situated in a position on the mold that is frequently flexed. It will also hinder the flexibility of the mold in that location.

Example of Repairing a Block Mold with PolyBond

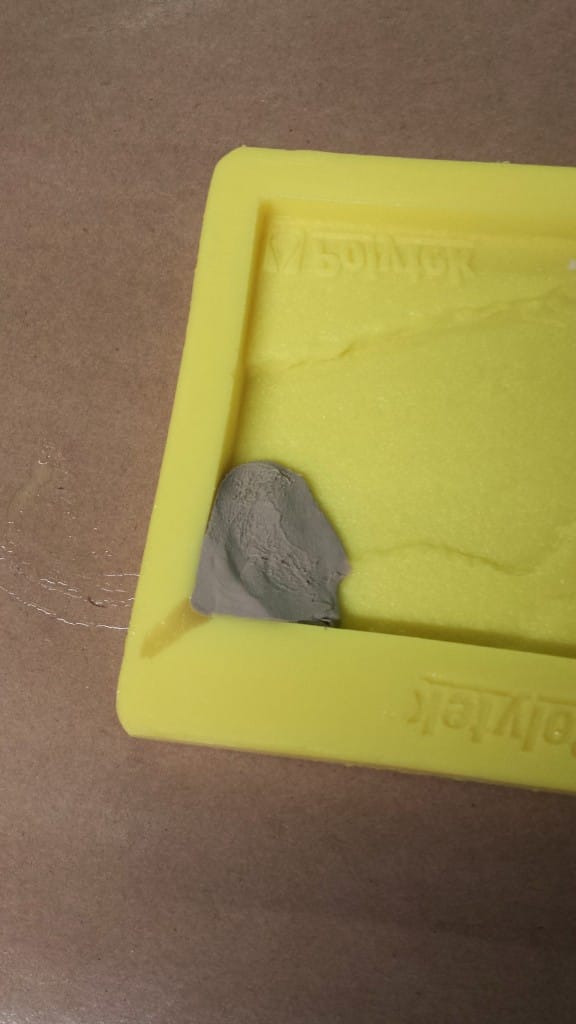

This Poly 74-20 polyurethane rubber coaster mold has a tear in the corner:

Cut around the tear to expose clean rubber (PolyBond will adhere much better to clean rubber, as opposed to rubber that is contaminated with release agent, casting materials, etc.):

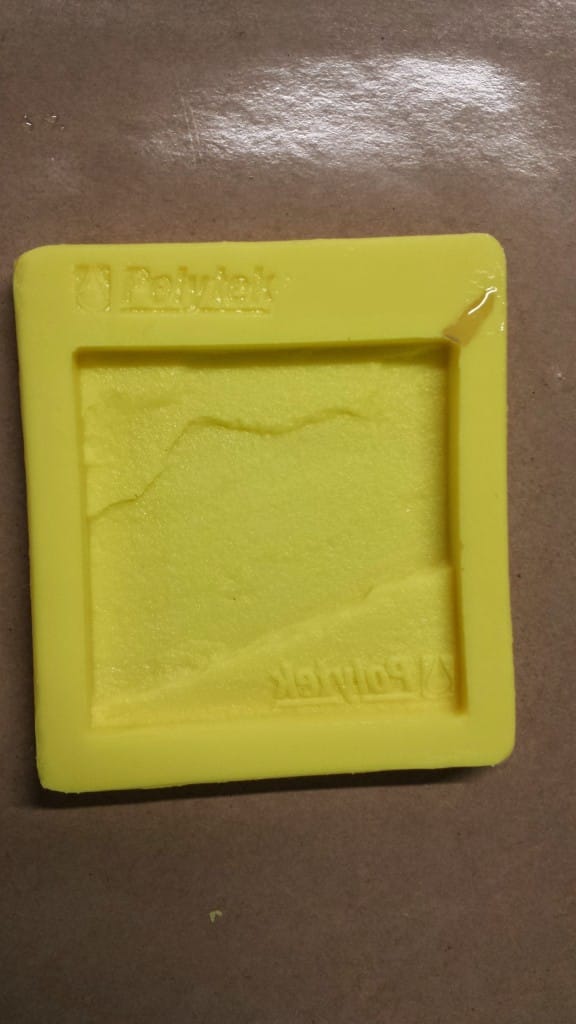

The new cut:

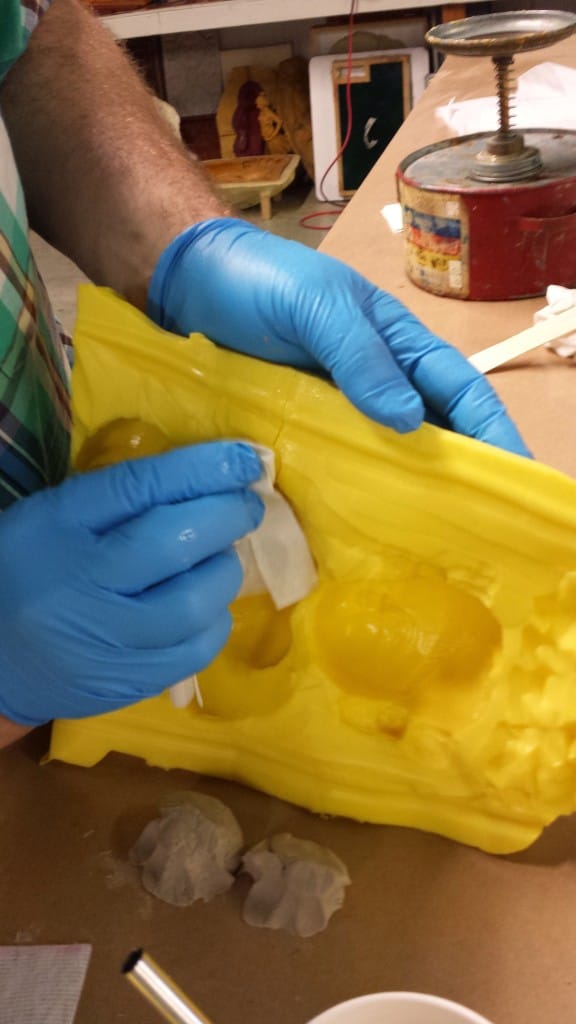

Either position the original model in the mold or use a different material to recreate the shape of the model to prevent PolyBond from leaking. Plasticine clay is used here:

Carefully weigh and mix PolyBond at a 1A:3B mix ratio. It has a 3-minute working time, so application of this adhesive should be done quickly after mixing:

Apply PolyBond to the interior of the cut:

Remove excess PolyBond and allow it to cure (~15 minutes):

Cured PolyBond:

Example of Repairing a Poured Blanket Mold with PolyBond

Blanket molds are generally thinner than block molds and can be more difficult to repair.

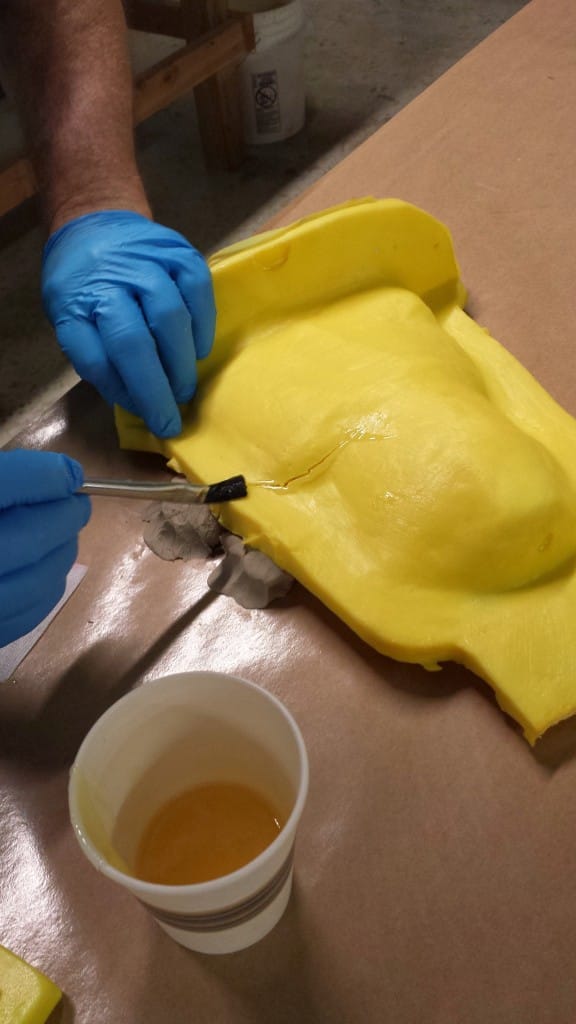

Clean the affected area with a solvent cleaner, like denatured alcohol (be aware of health and flammability risks with these solvents):

Apply PolyBond to the interior of the tear:

Remove excess PolyBond:

Apply PolyBond to the exterior surface of the tear:

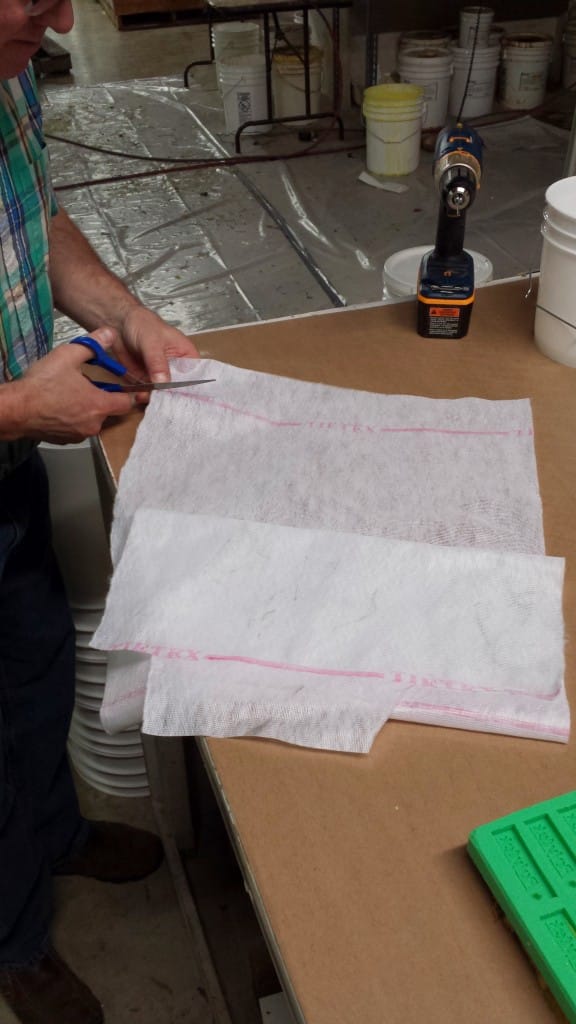

Before mixing the PolyBond, a piece of Tie-Tex ® Fabric was cut to position over the tear for increased reinforcement:

Ensure that the Tie-Tex ® Fabric fully covers the tear:

Apply PolyBond over the fabric:

Allow PolyBond to cure:

The flexibility of PolyBond makes it ideal for repairing flexible polyurethane; however, it does have a Shore hardness of ~A50, so if you’re working with a very soft rubber (Shore A20), it may interfere with the flexibility of the mold depending on the location of the tear.

Repairing Silicone Rubber Molds

If a small tear occurs in a platinum-cured silicone rubber or tin-cured silicone rubber, a good product to use for the repair is TinSil® 80-30 Silicone Rubber . Traditionally used to make molds, this two-part, Shore A30 silicone also serves as a great adhesive. TinSil ® 80-30 has a mix ratio of 1A:10B, a pour time of 45 minutes, and a cure time of 24 hours. Because the cure time of this product is 24 hours, it is important to situate the ends of the tear in a stable position that will remain unchanged for at least 24 hours.

The techniques used on polyurethane molds, as shown above, can also be used when repairing silicone molds.