Celebrating St. Patrick's Day with Resin Casting [Beer-Filled Mug Replicas]

For St. Patrick’s Day this year, we used EasyFlo Clear Liquid Plastic to make replicas of beer-filled mugs. This resin casting project makes great decorations for restaurants, bars, and parties.

Here is what you’ll need to make these:

- Beer mugs [or pitchers, pint glasses, etc.]

- EasyFlo Clear Liquid Plastic

- Water

- PolyColor Dyes [optional]

CAUTION: Polyurethane plastics (like EasyFlo Clear) will produce exotherm, so it is important to exercise caution especially when working with glass mugs or containers as cracking can occur.

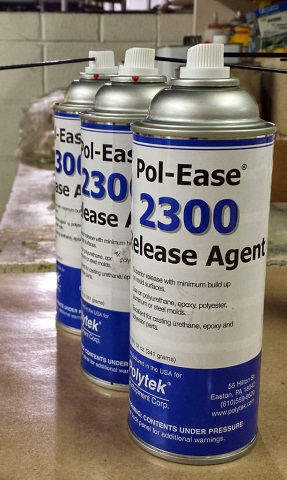

Step One: Spray Release Agent into the Mug [OPTIONAL]

If you would like to remove the plastic from the mug [picture on left] once it has cured, release agent should be applied to the mug or cup before pouring the resin. Make sure that the mug that you choose has enough positive draft to remove the casting. You might consider using a paper cup so you can cut the cup away from the casting. If you intend to keep the plastic in the mug or container [picture on right], a release agent is not necessary.

Pol-Ease® 2300 Release Agent is a suitable option if one is necessary:

Step Two: Mix EasyFlo Clear Casting Resin (scroll to bottom to read about adding colored dyes)

EasyFlo Clear is a two-part polyurethane plastic. It has a 1A:1B mix ratio by volume (100A:90B mix ratio by weight) and needs to be thoroughly mixed.

This liquid plastic has a 2 – 2.5 minute pour time, so it’s important to work in a timely manner. Determine the amount of plastic you will need based on the size of your mug – remember to leave space at the top for foam (added later).

Step Three: Pour Mixed EasyFlo Clear into Mug

Once poured, allow this EasyFlo Clear mix to cure for 5 to 10 minutes before adding the “foam” mix.

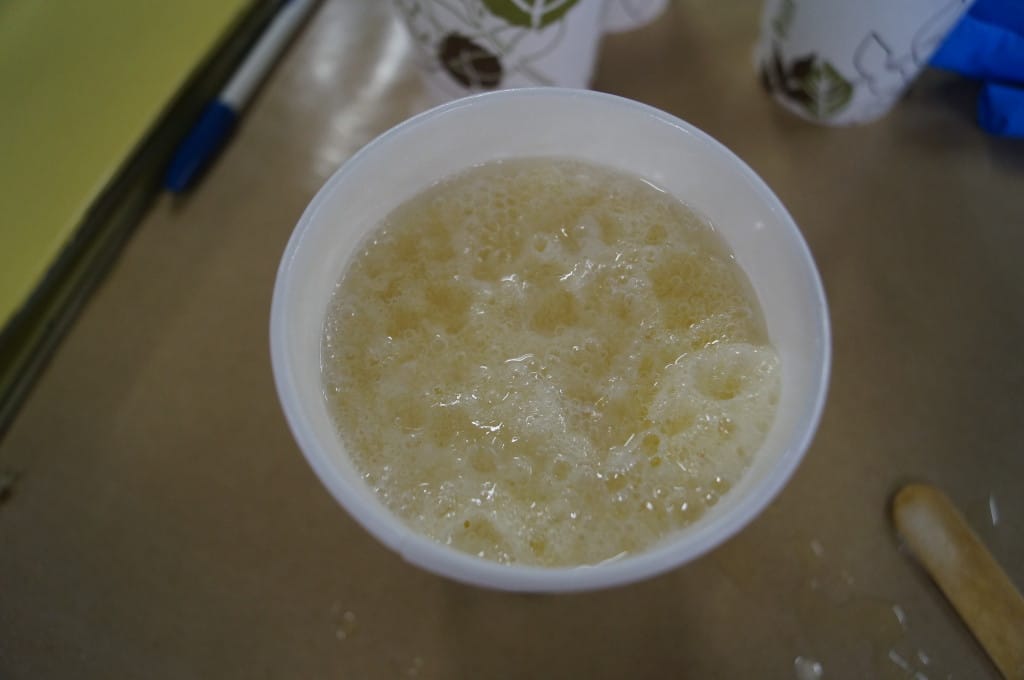

Step Four: Make Foam from EasyFlo Clear and Water

Polyurethane plastics are moisture-sensitive and will foam when in contact with water (normally, we would recommend deliberately avoiding water when working with these materials). To make the foam, mix the EasyFlo Clear in the same manner as the last batch (1A:1B by volume or 100A:90B by weight) and then add 50% water and mix.

Step Five: Pour Foam Mixture on top of Cured EasyFlo Clear

The foam mixture will expand, so ensure that there is enough space to accommodate that expansion at the top of the mug.

After pouring, allow EasyFlo Clear to cure approximately 15-30 before handling it.

EasyFlo Clear can be Colored using PolyColor Dyes

PolyColor Dyes can be added to EasyFlo Clear to achieve different colors. We used Green PolyColor Dye and Brown PolyColor Dye to achieve these looks [below]. Dye options include black, brown, blue, green, yellow, red, and white.