A Selection Guide: Sealers & Release Agents for Mold Making & Casting

Many mold making and casting projects require the use of an appropriate sealer and/or release agent. In the realm of mold making and casting, these two products are broadly defined as follows:

Sealer- a material that seals small pores/holes so that liquid mold material cannot penetrate the surface. Sealers fall into three general categories: permanent, semi-permanent and removable.

Release Agent– a coating that is applied to prevent liquid rubbers and resins from sticking to surfaces. Release agents can be categorized into two general categories: those used for mold making and those used for casting (one release agent can be used for both purposes in some instances).

In the Polytek® Sealers & Release Agents Selection Guide, the following products are featured (brief descriptions are listed below):

|

Polytek® Product |

Sealer | Release Agent |

Use On Model or In Cured Mold |

Description |

|

√ |

√ |

Both |

Water-soluble, alcohol-based sealer for porous models. Also acts as barrier coat when casting in cured molds. Available in clear or green. Can be applied to models for use with liquid polyurethane and liquid silicone rubber. Should only be applied to cured polyurethane molds. |

|

|

√ |

√ |

On Model Only |

White petrolatum dissolved in mineral spirits. This semi-permanent option can serve as a sealer and/or release agent. Can be applied to models for use with liquid polyurethane and liquid silicone rubber. |

|

|

√ |

√ |

Both |

Semi-permanent, silicone-based sealer and release agent. Can be applied to models for use with polyurethane and platinum-cured silicone rubbers (not recommended for tin-cured silicone rubbers). Can be applied to cured polyurethane, platinum-cured silicone, and tin-cured silicone rubber molds. |

|

|

√ |

Both |

Silicone-based, aerosol spray release agent for use on non-porous or sealed models. Should only be used with polyurethane rubber. |

||

|

√ |

On Model Only |

Solvent and silicone-based release agent for use on models before pouring liquid rubber. Fast drying, but flammable. Should only be applied to models for use with liquid polyurethane rubber. |

||

|

√ |

Both |

Aerosol spray release agent that can be washed off of models and castings. Preferred choice when castings need to be painted. Can be applied to models for use with liqiud silicone rubbers, but is not recommended for use with liquid polyurethane rubber. Can be applied to cured polyurethane and silicone rubber molds, but may affect mold life of cured polyurethane rubber. |

||

|

√ |

In Cured Mold Only |

Water-based release agent designed for use when casting concrete or plaster. Should only be applied to cured polyurethane rubber molds. |

||

|

√ |

In Cured Mold Only |

Silicone-free, oil-based release agent designed for use when casting concrete or plaster. Should only be applied to cured polyurethane rubber molds. |

For detailed descriptions of each option, please read the entire Selection Guide .

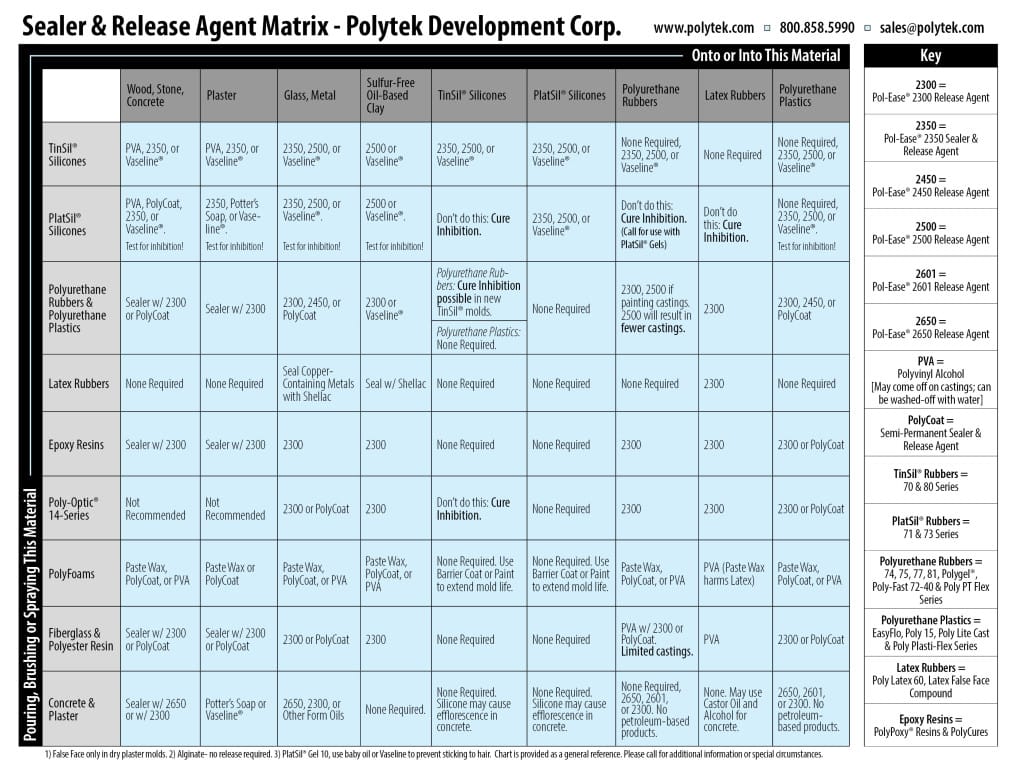

A Sealer & Release Agent “Matrix” is also included in the document for quick reference (page 4).

This chart is provided as a general reference. Please call for additional information or special circumstances.

Sealer & Release Agent options can also be viewed on www.polytek.com:

- Release Agents & Sealers for Mold Making

- Release Agents & Sealers for Casting