Tek-Tip: Reduce Bubbles in Clear Casting Resin

Without the proper equipment, it can be difficult to achieve bubble-free castings with clear polyurethane casting resins such as Polytek Poly-Optic® 14-Series resins. These clear resins are two-part

polyurethane systems formulated specifically for applications where optical clarity is

needed.

[below: an example of Poly-Optic casting (left) next to the original model (right)]

In this article, we discuss three different methods for casting Poly-Optic® 1411 Clear

Casting Resin. Each method produces varying levels of bubbles in the final

casting.

Casting Methods

- Open Pour

- Vacuum Degassing

- Pressure Casting

NOTE: Some of these methods require special equipment; always seek the advice of

a professional when sourcing and using this type of equipment.

In each method, the first step is to measure and mix the resin. Poly-Optic 1411 has a mix ratio of 1A:1B by volume

(100A:90B by weight).

In all three method examples below, a small polyethylene container will serve as the mold.

Open Pour Method

The open pour method does not involve any special equipment. After mixing Parts A & B together, simply pour the

resin into a properly prepared mold and allow it to cure.

Vacuum Degassing

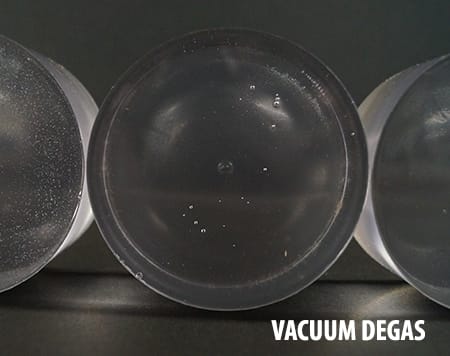

Vacuum degassing requires a vacuum chamber, which can be expensive. To degas, the mixed resin is placed inside a

container and then placed inside the vacuum chamber. The container holding the resin should have enough headspace to

accommodate three times the original volume of the resin.

Vacuum is pulled to 29 inches of

mercury.

The air is sucked out of the resin which causes the bubbles to rise

up and then collapse. This process typically takes a couple of minutes. NOTE: Resins with short working

times should not be vacuum degassed.

When the resin is removed from the chamber, it appears

bubble-free.

The resin is then poured into the mold. Although the resin has been degassed, bubbles may be generated in this step.

Pressure Casting

To pressure-cast a part, the resin should be mixed and poured into the desired mold prior to placing it in the pressure pot. Pressure casting essentially crushes the air bubbles in the resin.

NOTE: Molds must be made under the same pressure or deformation may occur.

We

recommend setting the pressure pot at 60 psi; the closer to 100 psi, the better.

The mold should remain in the pressure pot for the length of the demold time.

The Results

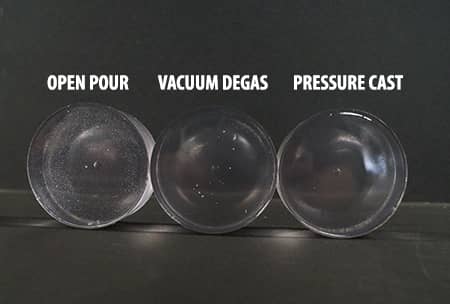

The open pour method results in

hundreds of tiny air bubbles which are quite obvious in the final casting.

The vacuum-degassed casting is an improvement, but the act of pouring the degassed

resin into the mold produced some air bubbles.

The resin cast under pressure resulted in the casting with the least air

bubbles.

The recommended casting method for bubble-free,

clear parts is pressure casting.