Tek-Tip: Understanding Physical Property Specifications for Rubbers & Plastics

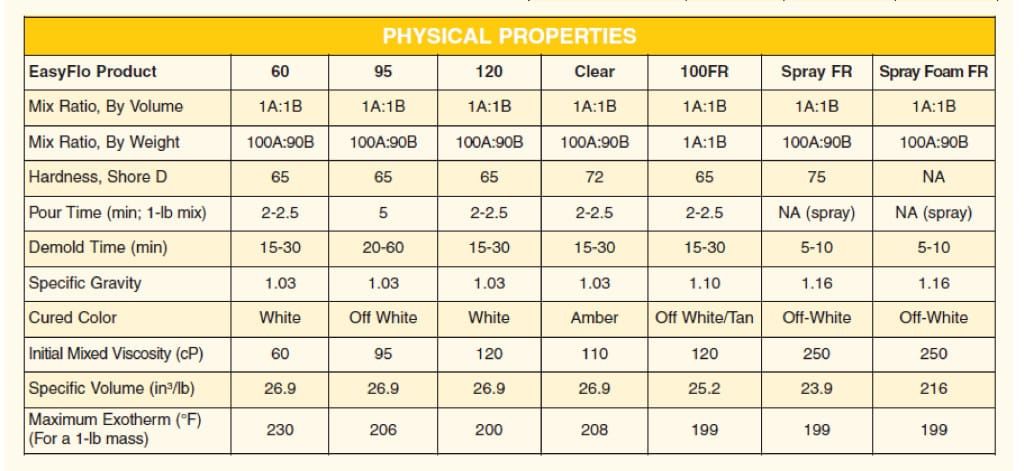

Our Product Catalog, Website, Technical Bulletins and Physical Property Bulletins are full of technical specifications. They often appear in large tables, like this:

The EasyFlo Series (Liquid Plastic) Physical Properties Chart

This information can be overwhelming for those that don’t have much experience with rubbers and plastics, so we would like to outline the general meaning of each specification:

Mix Ratio

![]()

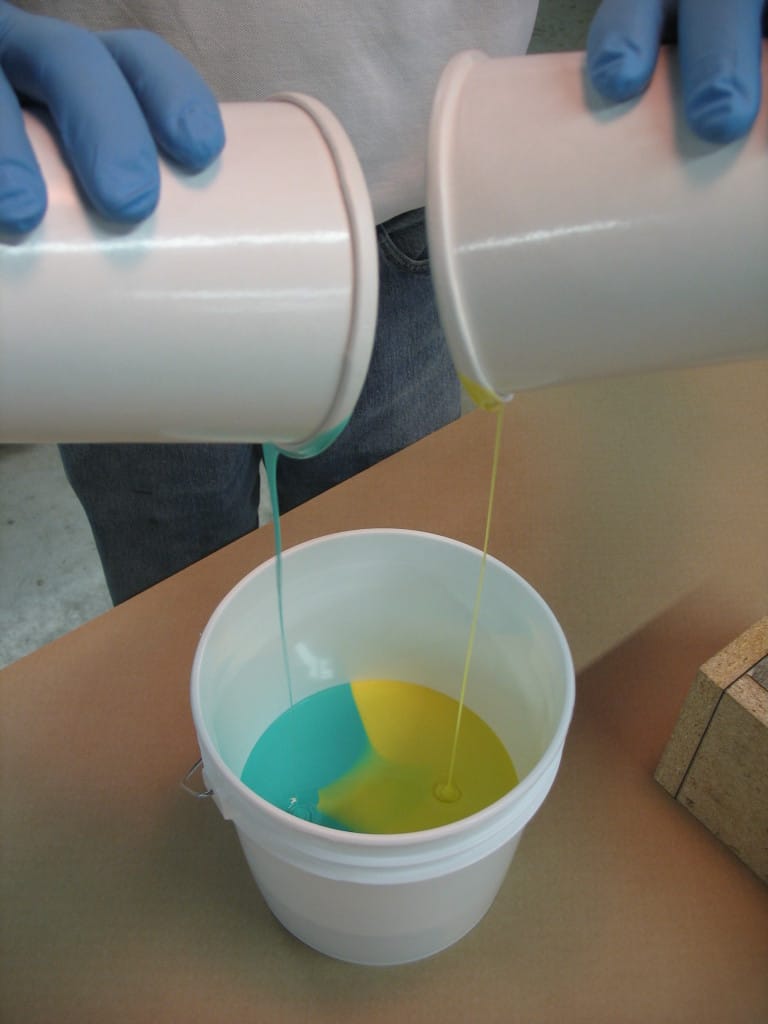

The great majority of Polytek products are two-part systems: Part A & Part B. The mix ratio indicates the amount of Part A and Part B needed relative to each other. When these two parts are mixed together at the proper ratio, they cure at room temperature. It is imperative to stay on-ratio to ensure a successful cure – off-ratio mixes can result in subpar final products or mixes that do not cure at all.

Mix ratios vary from product to product, even within the same series (e.g., The EasyFlo Series).

In some cases, you will find that two different mix ratios are given: one by weight and one by volume.

Shore Hardness

![]()

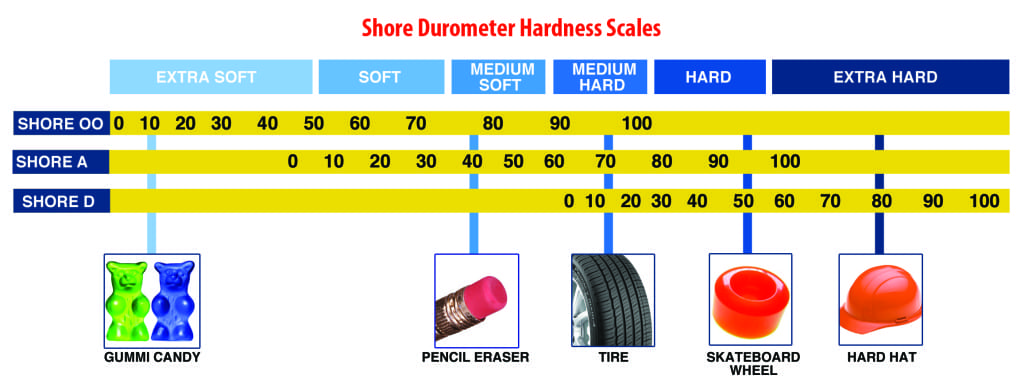

The hardness of our rubbers and plastics are measured on Shore Hardness Scales. The device used to measure hardness is called a durometer.

Rubbers are measured using the Shore OO Scale and A Scale. Very hard rubbers and plastics are measured using the Shore D scale. The higher the number, the harder the material.

For more information on Shore hardness scales, read this dedicated article, or watch the following video:

Pour Time

![]()

Pour time, listed in minutes, is the amount of time you have, after adding Part A and Part B together, before the mixture cures to a point where it is no longer able to flow. Ideally, the product should be mixed and poured into a mold or over a model in half of the pour time. The EasyFlo Series, which is featured in the table above, has some of the shortest working times of all Polytek products.

Demold Time

![]()

Demold time, listed in either minutes or hours, is the amount of time you should wait (starting at the end of the pour time) before removing a casting from a mold or before removing a mold from a model. This does not mean that the mold is ready for use (for casting) at this point. For instance, polyurethane rubber molds do not obtain final cure properties for up to seven days; however, molds can typically be used, with care, 24 to 48 hours after demolding. Demolding or using the mold too soon may deform it.

Specific Gravity

![]()

Specific gravity indicates how much more or less dense the product is compared to water. Water has a specific gravity of 1.00 gram/cm³. Products with a specific gravity greater than 1 are more dense than water; products with a specific gravity of less than 1 are less dense than water.

Cured Color

![]()

Cured color is the color that the product naturally cures to; some products are transparent and some are opaque. In many cases, the cured color will not always be the same in individual products (e.g., the kit of 75-Series polyurethane rubber that you’re using this month may not have the same cured color as the kit you order 6 months from now). Part Bs of certain products (i.e., aromatic products) darken with age, resulting in a darker cured color.

Cured color can be changed with the use of PolyColor Dyes (for polyurethane products) and SiliColor Silicone Pigments (for silicone products).

Initial Mixed Viscosity

![]()

Viscosity, listed in centaPoise (cP), is the resistance of a substance to flow. For example, water has a lower viscosity than molasses and flows more easily.

In this case, the Initial Mixed Viscosity is the viscosity of Part A and Part B once they are combined. The EasyFlo Series, featured above, has some of the lowest viscosities of all Polytek product lines.

Here are some examples of the viscosities of common materials:

Water: 1 cP

SAE 30 Motor Oil: 500 cP

Honey: 10,000 cP

Sour Cream: 100,000

cP

Peanut Butter: 250,000 cP

Specific Volume

![]()

This specification identifies the number of cubic inches occupied by one pound of material (in³/lb). This number is necessary to determine how much rubber or plastic is needed to occupy a given space.

Maximum Exotherm (°F)

![]()

This specification is generally only listed for Polytek polyurethane and epoxy resins – it indicates the maximum amount of heat (°F) generated when curing. There will also be a note indicating the mass of the sample used in determining this number.